When selecting engineered hardwood flooring, even a small difference in thickness can have a significant impact on durability and stability. Understanding the differences between 3/8 inch and 1/2 inch options is crucial in making an informed decision. Let’s explore the advantages of each to help you choose the right flooring for your needs.

Key Takeaways:

- The thickness of engineered hardwood flooring can affect its durability and stability.

- Thicker flooring, like 1/2 inch, usually offers better resistance to heavy foot traffic and reduces the risk of warping or buckling.

- Consider factors such as the type of wood, installation environment, and previous flooring thickness when selecting the right thickness.

- For heated flooring, a maximum thickness of 1/2 inch is recommended for efficient heat transfer.

- The best thickness for engineered hardwood flooring is typically between 3/4 inch and 5/8 inch, with a 3/16 inch wear layer and a 9 or 11-ply backing layer.

Solid Hardwood vs Engineered Hardwood

When it comes to choosing the right flooring for your home, two popular options to consider are solid hardwood and engineered hardwood. While both types of flooring have their advantages, understanding the differences between them can help you make an informed decision. Let’s take a closer look at solid hardwood and engineered hardwood to see which one is the best fit for your needs.

Solid Hardwood Flooring

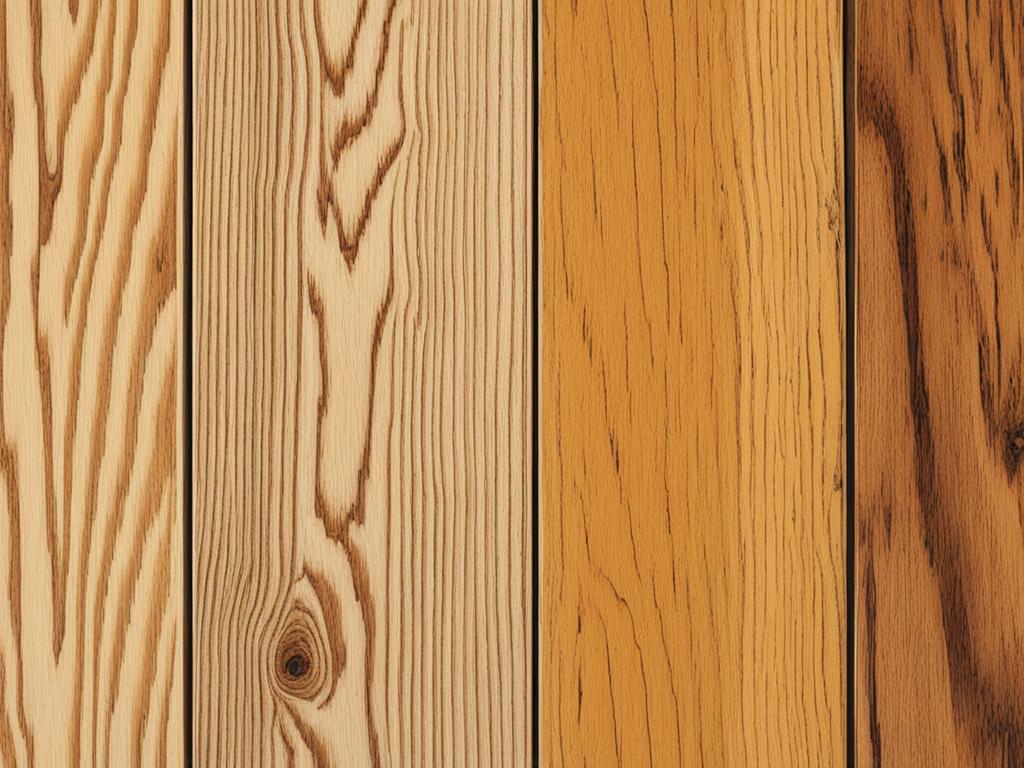

Solid hardwood flooring is made from a single piece of wood and is known for its timeless beauty and durability. With solid hardwood, you have the option to choose from various thicknesses, including 3/8 inch and 1/2 inch. This type of flooring adds warmth and elegance to any room and can be refinished multiple times to maintain its original beauty.

Engineered Hardwood Flooring

Engineered hardwood flooring, on the other hand, is constructed with multiple layers. The top layer is made of real hardwood, while the backing layers are typically composed of plywood. Engineered hardwood flooring also comes in different thicknesses, including 3/8 inch and 1/2 inch. This type of flooring offers added stability and is less prone to shrinking or expanding due to changes in humidity.

One of the advantages of engineered hardwood flooring is its versatility. It can be installed in areas where solid hardwood may not be recommended, such as basements or rooms with radiant heating systems. Additionally, engineered hardwood is generally more cost-effective than solid hardwood, making it a popular choice for homeowners.

Comparing Solid Hardwood and Engineered Hardwood

When comparing solid hardwood and engineered hardwood, there are a few key factors to consider. While solid hardwood offers the classic beauty and durability that many homeowners desire, engineered hardwood provides greater flexibility in terms of installation options. Additionally, engineered hardwood is more resistant to moisture and temperature changes, making it a practical choice for areas with fluctuating climate conditions.

“Solid hardwood flooring offers timeless beauty and durability, while engineered hardwood provides greater flexibility and resistance to moisture. It ultimately depends on your specific needs and preferences.”

Whether you choose solid hardwood or engineered hardwood, both options offer a wide range of hardwood species, colors, and finishes to suit your aesthetic preferences. It’s important to consider factors such as the installation environment, budget, and maintenance requirements when making your decision.

Ultimately, the choice between solid hardwood and engineered hardwood comes down to personal preference and factors such as the location and purpose of the flooring, as well as budget considerations.

In the next section, we will explore the advantages of thicker flooring and how it can impact the durability and stability of your hardwood floors.

The Advantages of Thicker Flooring

Thicker hardwood flooring, such as 1/2 inch, offers several advantages when compared to thinner options like 3/8 inch. The additional thickness provides enhanced stability and durability, making it better suited to withstand heavy foot traffic and reducing the risk of warping or buckling over time. This is particularly important in high-traffic areas of your home, such as hallways and living rooms.

By opting for thicker flooring, you can ensure a longer lifespan for your hardwood floors, as they will be better able to handle the demands of daily use. Thicker flooring also provides a more substantial feel underfoot, lending a sense of quality and luxury to your space.

However, when deciding on the thickness of your engineered hardwood flooring, it’s crucial to consider other factors as well. The type of wood and the installation environment play significant roles in determining the ideal flooring thickness for your specific needs.

Thicker flooring, while beneficial in terms of stability and durability, may require additional adjustments to door heights and skirting boards during installation. It’s essential to factor in these potential modifications to ensure a seamless and visually appealing end result.

Ultimately, the choice between 3/8 inch and 1/2 inch engineered hardwood flooring depends on your specific requirements and preferences. By considering the advantages of thicker flooring and assessing the suitability for your space, you can confidently make an informed decision that will enhance the beauty and functionality of your home.

Understanding Engineered Hardwood Thicknesses

When considering engineered hardwood flooring, one important factor to take into account is the thickness of the flooring. Engineered hardwood is available in various thicknesses, typically ranging from 3/8 inch to 1/2 inch. This thickness plays a role in the durability, ability to be sanded, and ease of installation of the flooring.

The wear layer of engineered hardwood, which is the top layer made of real hardwood, can also vary in thickness. A common measurement for the wear layer is 3/16 inch. This layer contributes to the overall aesthetic appeal and longevity of the flooring.

Additionally, the backing layer or core of engineered hardwood is usually made of plywood and may feature 9 or 11 plies. The quality and construction of the backing layer can impact the stability and strength of the flooring.

Comparing Engineered Hardwood Thicknesses

| Thickness | Wear Layer Thickness | Backing Layer |

|---|---|---|

| 3/8 inch | 3/16 inch (common) | Usually 9 plies of plywood |

| 1/2 inch | 3/16 inch (common) | Usually 11 plies of plywood |

Choosing the right thickness for your engineered hardwood flooring depends on several factors, including your preferences, the desired durability, and the installation environment. Thicker flooring generally provides enhanced stability and durability, but it may require adjustments to door heights and skirting boards.

In conclusion, understanding the different thickness options for engineered hardwood flooring can help you make an informed decision based on your specific needs and preferences. By considering the wear layer thickness, backing layer construction, and overall thickness of the flooring, you can select the most suitable option to enhance the beauty and longevity of your space.

Factors to Consider When Choosing Thickness

When selecting the thickness of your engineered hardwood flooring, several factors should be taken into account to ensure the best fit for your needs. These factors include the amount of foot traffic in the area, the previous flooring thickness, and whether you have heated flooring. By considering these elements, you can make an informed decision and achieve the ideal balance of durability, cost-effectiveness, and convenience.

Foot Traffic

The level of foot traffic in an area plays a crucial role in determining the appropriate thickness of the engineered hardwood flooring. High-traffic areas require thicker flooring to withstand the constant wear and tear. On the other hand, low-traffic areas may not require as much thickness. By assessing the typical foot traffic in the location where the floor will be installed, you can better understand the level of durability needed.

Previous Flooring Thickness

If you are replacing an existing floor, it is beneficial to match the thickness of the previous flooring. This can help reduce costs by eliminating the need for adjustments to door heights and skirting boards. Additionally, matching the thickness can make the installation process smoother and more efficient.

Heated Flooring

If you have heated flooring, it is crucial to select a maximum thickness of 1/2 inch for efficient heat transfer. Thicker flooring may hinder the effectiveness of the heating system and result in wasted energy.

Recommended Thickness

While there is no one-size-fits-all answer, the best thickness for engineered hardwood flooring typically falls between 3/4 inch and 5/8 inch. It is also recommended to opt for a 3/16 inch wear layer and a 9 or 11-ply backing layer to ensure optimal durability and stability.

| Factors to Consider | Thickness Recommendation |

|---|---|

| Foot Traffic | Assess the level of foot traffic in the area. Higher foot traffic warrants thicker flooring for enhanced durability. |

| Previous Flooring Thickness | Matching the previous flooring thickness can streamline installation and reduce costs. |

| Heated Flooring | Select a maximum thickness of 1/2 inch for efficient heat transfer. |

| Overall Recommendation | It is recommended to opt for a thickness between 3/4 inch and 5/8 inch, with a 3/16 inch wear layer and a 9 or 11-ply backing layer. |

By considering these factors and adhering to the recommended thickness guidelines, you can choose the perfect engineered hardwood flooring for your space. It is important to find the right balance between durability, aesthetic appeal, and practicality to ensure long-lasting satisfaction with your flooring choice.

Conclusion

When it comes to choosing between 3/8 inch and 1/2 inch engineered hardwood flooring, there are several important factors to consider. Durability, stability, and ease of installation are key considerations in making the right decision for your home.

Thicker flooring options, such as 1/2 inch, generally offer more stability and durability. They can better withstand heavy foot traffic and reduce the risk of warping or buckling. However, it’s crucial to take into account other factors, such as the type of wood and the installation environment. These factors can impact the overall performance and longevity of your flooring.

Ultimately, the best thickness for engineered hardwood flooring is typically between 3/4 inch and 5/8 inch, with a 3/16 inch wear layer and a 9 or 11-ply backing layer. This combination ensures both durability and stability while maintaining an aesthetically pleasing appearance.

By carefully considering these factors and consulting with flooring professionals, you can make an informed decision and choose the right hardwood flooring option for your specific needs and preferences.

FAQ

What is the difference between 3/8 inch and 1/2 inch engineered hardwood flooring?

The difference lies in the thickness of the flooring. 1/2 inch engineered hardwood flooring is thicker and generally offers more stability and durability compared to the thinner 3/8 inch option.

What is the difference between solid hardwood and engineered hardwood?

Solid hardwood is made from a single piece of wood, while engineered hardwood is constructed with multiple layers and a top layer of real hardwood. Both options are available in 3/8 inch and 1/2 inch thicknesses.

Why is thicker flooring generally more stable and durable?

Thicker flooring, such as 1/2 inch, can withstand heavy foot traffic better and reduce the risk of warping or buckling. However, other factors, such as the type of wood and installation environment, also play a role in determining durability and stability.

How does the thickness of engineered hardwood flooring impact its durability?

The thickness of the engineered hardwood flooring can affect its durability. Thicker flooring tends to be more durable and can withstand more wear and tear over time.

What factors should I consider when choosing the thickness of engineered hardwood flooring?

Factors to consider include the foot traffic in the area, the previous flooring thickness, and whether you have heated flooring. For efficient heat transfer, it’s recommended to choose a maximum thickness of 1/2 inch for heated flooring. Matching the thickness of your previous flooring can help reduce costs and make installation easier.

What is the ideal thickness for engineered hardwood flooring?

The recommended thickness for engineered hardwood flooring is typically between 3/4 inch and 5/8 inch, with a 3/16 inch wear layer and a 9 or 11-ply backing layer. This thickness provides a good balance of stability, durability, and ease of installation.