Have you ever wondered how carpets are made? The process of carpet manufacturing is a fascinating journey that involves careful selection of raw materials, intricate weaving or tufting techniques, and precise finishing touches. In this article, we will take a closer look at the step-by-step process of creating carpets, from the choice of materials to the final product ready for installation.

Key Takeaways

- Carpet manufacturing involves selecting raw materials, transforming them into yarn, and weaving or tufting the yarn into the desired carpet structure.

- Homeowners can choose between natural fibers like wool and synthetic fibers like nylon or polyester when it comes to selecting carpet materials.

- The journey of carpet production starts with obtaining raw materials, which can be natural or synthetic fibers.

- Carpet dyeing is a crucial step that gives color to carpets, with options for both natural dyeing using plant-based dyes and synthetic dyeing using chemically produced dyes.

- Weaving and tufting techniques are used to craft the final carpet structure, offering unique patterns and designs.

Understanding the Basics of Carpet Materials: A Tale of Natural vs. Synthetic Fibers

When it comes to choosing the right carpet for your home, one of the key factors to consider is the type of fibers used. Carpets can be made from natural fibers, such as wool, or synthetic fibers, like nylon and polyester. Each type has its own unique characteristics and advantages.

The Appeal of Natural Fibers

Natural fibers, like wool, are derived from animal hair or plant sources. Wool is one of the most popular natural materials used in carpet manufacturing. It offers a luxurious and warm feel underfoot, making it a perfect choice for areas where comfort is a top priority, such as bedrooms and living rooms.

“Natural fibers like wool provide a luxurious and warm feel.”

In addition to its comfort, wool also has natural stain resistance and flame-retardant properties, making it a durable and safe choice for homes. However, wool carpets tend to be more expensive than those made from synthetic fibers.

The Strength of Synthetic Fibers

Synthetic fibers, on the other hand, are man-made materials that are specifically engineered for carpet production. Nylon and polyester are two commonly used synthetic fibers in the industry. They offer several advantages over natural fibers, including enhanced durability and stain resistance.

“Synthetic fibers offer benefits such as durability and stain resistance.”

Nylon, known for its strength and resilience, is an excellent choice for high-traffic areas such as hallways and family rooms. It is highly resistant to wear and tear, making it a long-lasting option for households with pets and children. Polyester, on the other hand, is a more affordable alternative that offers excellent color retention and softness.

Considering Aesthetics and Durability

When choosing between natural and synthetic fibers, it is important to consider your aesthetic preferences and desired level of durability. Natural fibers like wool often provide a timeless and classic look to any room, but they may require more maintenance and care to keep them looking their best.

On the other hand, synthetic fibers come in a wide range of colors, patterns, and styles, allowing you to find the perfect carpet to match your interior design. They are generally easier to clean and maintain, making them a practical choice for busy households.

Ultimately, the choice between natural and synthetic fibers depends on factors such as budget, lifestyle, and personal preferences. It is important to weigh the pros and cons of each type before making your decision.

In the next section, we will delve deeper into the journey of carpet production, exploring the step-by-step process of transforming raw materials into beautiful carpets.

From Raw Materials to Carpet Fibers: A Step-by-step Journey

The journey of carpet production involves a fascinating process that begins with carefully selected raw materials. These materials serve as the foundation for creating the carpet fibers that contribute to the overall beauty and functionality of carpets.

The Power of Natural Fibers

One type of raw material used in carpet production is natural fibers. These fibers are derived from organic sources such as plants and animals. Wool, for example, comes from the shearing of sheep and is highly valued for its softness, durability, and natural insulation properties. Other natural fibers used in carpet production include sisal, seagrass, and jute.

The Science of Synthetic Fibers

On the other hand, synthetic fibers are manufactured through advanced technological processes. Materials like nylon and polyester are melted and extruded into long strands to create synthetic fibers. Nylon carpets are known for their excellent durability and resistance to wear and tear, making them a popular choice for high-traffic areas. Polyester carpets, on the other hand, offer excellent stain resistance and vibrant color options.

Once the raw materials have been obtained, they undergo further processing to transform them into carpet fibers suitable for weaving or tufting. This involves various mechanical and chemical processes, depending on the type of fiber being produced.

For natural fibers like wool, the next step involves carding, which aligns the wool fibers and eliminates any impurities. The fibers are then spun into yarn using spinning wheels or machines. The resulting yarn is ready to be dyed and woven into a beautiful carpet.

Synthetic fibers, on the other hand, undergo a more scientific process. The raw materials are melted and extruded through spinnerets, which are small openings that shape the fibers. The fibers are then cooled and solidified, ready to be formed into yarn.

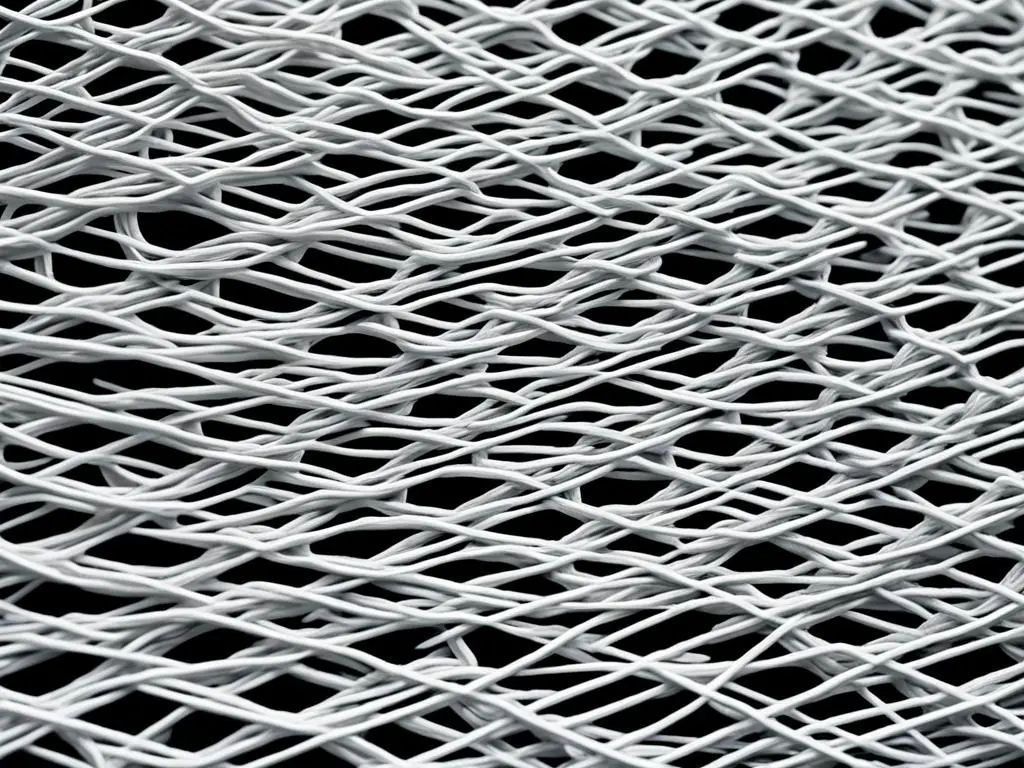

Once the carpet fibers are obtained, they are woven or tufted into the desired carpet structure. The weaving process involves interlacing the fibers together using traditional looms or modern weaving machines, creating intricate patterns and designs. Tufting, on the other hand, involves inserting yarn into a backing material to create a loop or cut pile surface.

Throughout the journey from raw materials to carpet fibers, each step requires precision, craftsmanship, and attention to detail. Whether it’s the natural beauty of silk carpets or the durability of synthetic fibers, the production process plays a significant role in creating carpets that enhance our homes and spaces.

The Art of Dyeing: Giving Color to Carpets

Carpet dyeing is a crucial step in the production process that brings vibrant hues to life. Whether it’s natural or synthetic dyeing, the goal is to achieve colorfastness and create carpets that are both visually striking and long-lasting.

Natural Dyeing: From Nature to vibrant colors

Natural dyeing involves extracting colors from plant-based, insect-based, or mineral-based sources. These dyes not only produce vibrant hues but also offer a sustainable and eco-friendly alternative to synthetic dyes. The process of dyeing with natural dyes is intricate and requires expertise. It starts with harvesting the desired plants or insects, which contain the natural coloring agents. These materials are then processed to extract the dyes, which are subsequently applied to the carpet fibers through various methods such as immersion or hand-painting.

One of the challenges with natural dyeing is achieving colorfastness. To address this, mordants are used. Mordants are substances that help fix the dye to the fibers, enhancing color retention and durability. Commonly used mordants include alum, iron, and tannin. The result is carpets with rich, natural colors that can age gracefully over time, showcasing a unique patina.

Synthetic Dyeing: A World of Color Options

Synthetic dyeing, on the other hand, relies on chemically produced dyes to offer a vast range of color options. Unlike natural dyes, synthetic dyes can be precisely formulated to achieve specific shades, allowing for endless creative possibilities. They are available in both liquid and powder forms, making them convenient to work with during the dyeing process.

Colorfastness is also crucial in synthetic dyeing. Manufacturers utilize various techniques and chemical treatments to ensure that the colors remain vibrant and fade-resistant over time. This includes pre-treatments, pH adjustments, and the use of fixing agents to enhance color retention.

A Feast for the Eyes: Carpets with Vibrant Hues

Whether dyed with natural or synthetic dyes, carpets are transformed into pieces of art through the dyeing process. The colors evoke emotions, set the mood, and enhance the overall aesthetics of any space. From subtle earth tones to bold, eye-catching hues, carpets can truly become the focal point of a room.

| Dyeing Method | Benefits | Considerations |

|---|---|---|

| Natural Dyeing |

|

|

| Synthetic Dyeing |

|

|

Crafting the Carpet: Weaving and Tufting Techniques

The final step in the carpet production process involves the intricate art of weaving and tufting. These techniques are essential for creating the desired carpet structure and bringing intricate patterns and designs to life.

Traditional weaving methods, particularly those used in silk carpet production, are renowned for their meticulous craftsmanship. Skilled artisans utilize intricate knotting techniques and operate traditional looms to weave the fibers together, creating exquisite carpets with rich textures and unparalleled beauty. The use of traditional weaving methods ensures that each carpet is a masterpiece, carefully crafted with time-honored techniques passed down through generations.

On the other hand, tufting is a more modern technique that has gained popularity in recent years. This method involves inserting yarn into a backing material to form loops or cut piles. With tufting, carpets can be produced more efficiently while still offering a wide variety of options in terms of patterns, colors, and textures. The flexibility of tufting allows for the creation of carpets that cater to the diverse tastes and preferences of homeowners, making it a popular choice in the industry.

Regardless of the technique used, both carpet weaving and tufting require a high level of skill, precision, and attention to detail to create carpets that are not only visually stunning but also durable and long-lasting. The expertise of the artisans, combined with the choice of high-quality materials, ensures that each carpet is a work of art that transforms any space into a showcase of elegance and style.