Air handlers play a vital role in regulating indoor air quality and maintaining comfortable temperatures in residential, commercial, and industrial settings. They are essential components of heating, ventilation, and air conditioning (HVAC) systems. However, one often overlooked aspect of air handlers is their weight, which can significantly impact installation, transportation, and maintenance processes.

Introduction to Air Handlers

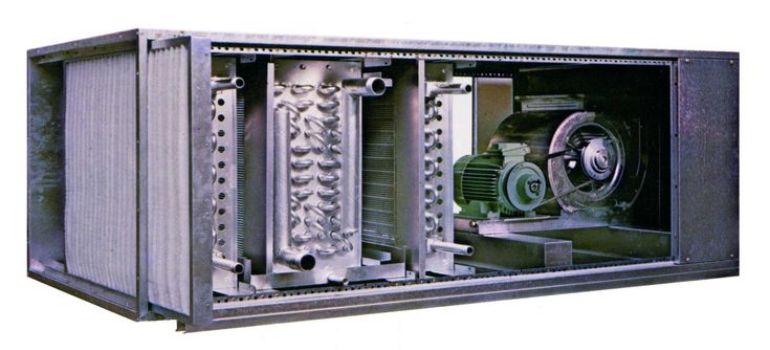

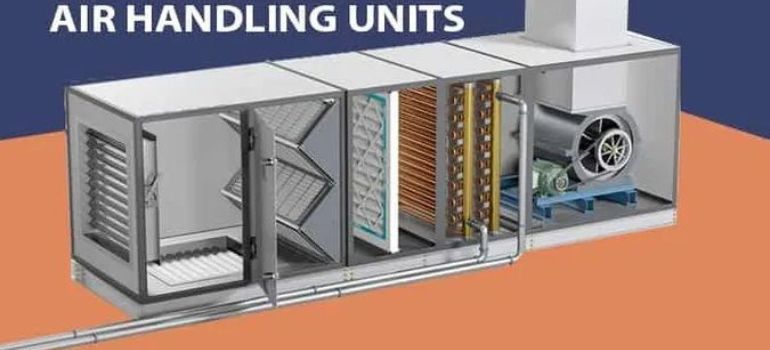

Before delving into the specifics of air handler weight, it’s crucial to understand what exactly an air handler is and how it functions within an HVAC system. An air handler is a device used to circulate and condition air as part of an HVAC system. It typically consists of a blower, heating and/or cooling elements, filters, and dampers.

Understanding Air Handler Weight

The weight of an air handler can vary significantly depending on several factors, including its size, design, and intended use. Residential, commercial, and industrial air handlers each have distinct characteristics that influence their weight.

Factors Influencing Weight

Several factors contribute to the overall weight of an air handler, including the materials used in its construction, the size and capacity of the unit, and the presence of additional features such as insulation or soundproofing.

Types of Air Handlers

Air handlers come in various types, each designed for specific applications. Common types include rooftop units, packaged air handlers, and split-system air handlers. Each type may have different weight considerations based on its design and intended use.

Average Weight of Residential Air Handlers

In residential settings, air handlers are typically smaller and lighter compared to their commercial and industrial counterparts. Standard residential air handlers designed for single-family homes usually weigh between 80 to 200 pounds, depending on their size and capacity.

Standard Sizes and Weights

Residential air handlers are available in different sizes to accommodate varying HVAC needs. A compact air handler designed for a small apartment may weigh around 80 pounds, while a larger unit suitable for a spacious home can weigh up to 200 pounds.

Commercial Air Handlers: Weight Considerations

Commercial air handlers are larger and more robust than residential units, catering to the heating and cooling needs of office buildings, retail spaces, and other commercial establishments. Due to their increased size and capacity, commercial air handlers can weigh anywhere from 200 to 1,000 pounds or more.

Larger Scale and Variability

The weight of commercial air handlers can vary significantly based on factors such as the size of the building, the number of occupants, and the specific requirements of the HVAC system. Larger buildings may require multiple air handlers, each contributing to the overall weight of the system.

Industrial Air Handlers: Heavyweight Solutions

In industrial settings, air handlers are used to maintain air quality and temperature control in large manufacturing facilities, warehouses, and other industrial environments. Industrial air handlers are typically much larger and heavier than their residential and commercial counterparts, with weights ranging from 1,000 to several thousand pounds.

Specialized Requirements

Industrial air handlers often have specialized features to meet the unique requirements of industrial applications, such as high-capacity filters, corrosion-resistant materials, and robust construction to withstand harsh operating conditions. These additional features contribute to the overall weight of the unit.

Transporting Air Handlers: Challenges and Solutions

Transporting air handlers, particularly larger and heavier units, can present logistical challenges. Proper handling and transportation methods are essential to ensure the safety of both the equipment and personnel involved.

Handling and Transportation Methods

Specialized equipment such as cranes, forklifts, and trucks with hydraulic lift gates may be required to transport heavy air handlers safely. Proper securing and bracing of the equipment during transit are necessary to prevent damage and ensure stability.

Installation: Dealing with Air Handler Weight

Installing air handlers requires careful planning and execution, especially in commercial and industrial settings where larger and heavier units are common. Safety measures must be implemented to prevent accidents and injuries during installation.

Safety Measures

Installation teams must adhere to strict safety protocols when handling and installing air handlers, including proper lifting techniques, the use of personal protective equipment (PPE), and ensuring adequate structural support for the unit.

Maintenance and Repair: Implications of Weight

The weight of an air handler can also impact maintenance and repair activities. Accessing internal components for routine maintenance or repairs may require additional effort and resources, particularly for larger and heavier units.

Accessibility and Support Structures

Maintenance personnel must have sufficient access to the air handler for servicing purposes. In some cases, additional support structures or equipment may be needed to safely access and work on the unit, adding to the overall maintenance cost.

Eco-Friendly Approaches to Lightweight Air Handlers

In recent years, there has been a growing emphasis on developing lightweight and energy-efficient air handlers to reduce environmental impact and operating costs. Innovations in materials and design have led to the development of eco-friendly air handler solutions that are both lightweight and highly efficient.

Innovations in Material and Design

Manufacturers are exploring alternative materials such as composite plastics and lightweight metals to reduce the weight of air handlers without compromising performance or durability. Advanced design techniques, such as optimized airflow patterns and variable-speed motors, further enhance energy efficiency and overall system performance.

Cost Implications of Air Handler Weight

The weight of an air handler can also impact its cost, both in terms of initial investment and long-term operating expenses. While lightweight air handlers may have a higher upfront cost due to the use of advanced materials and technology, they often offer significant savings over the life of the system through reduced energy consumption and maintenance requirements.

Initial Investment vs. Long-term Savings

When evaluating air handler options, it’s essential to consider not only the initial purchase price but also the long-term cost of ownership, including energy costs, maintenance expenses, and potential downtime due to repairs or replacements. Lightweight air handlers may offer a higher return on investment (ROI) over time compared to heavier, less efficient models.

Future Trends: Lightweight Air Handler Solutions

As technology continues to advance, the trend towards lightweight and energy-efficient air handlers is expected to accelerate. Manufacturers are investing in research and development to further improve the performance and sustainability of HVAC systems through innovative design and materials.

Technological Advancements

Future air handler solutions may incorporate advanced technologies such as artificial intelligence (AI) for predictive maintenance, smart sensors for real-time monitoring, and integrated renewable energy sources for enhanced sustainability. These advancements will not only reduce the weight and environmental impact of air handlers but also improve overall system reliability and performance.

Conclusion

The weight of an air handler is a crucial consideration that can impact installation, transportation, maintenance, and operating costs. Whether it’s a residential, commercial, or industrial application, choosing the right air handler with an optimal balance of weight, performance, and energy efficiency is essential for achieving comfort, reliability, and cost-effectiveness.

FAQs

While some residential air handlers may be installed by homeowners with the necessary skills and tools, it’s recommended to hire a professional HVAC technician for proper installation, especially for larger or more complex units.

Not necessarily. Lightweight air handlers can be just as durable as heavier units, depending on the materials and construction methods used. Proper maintenance and regular servicing are key to ensuring the longevity of any air handler.

The lifespan of an air handler can vary depending on factors such as usage, maintenance, and environmental conditions. On average, a well-maintained air handler can last 15 to 20 years or more.

Not necessarily. While heavier air handlers may have larger capacities and higher power ratings, performance ultimately depends on factors such as design, efficiency, and proper sizing for the specific application.

Yes, building codes and regulations may impose weight restrictions on HVAC equipment, including air handlers, to ensure structural integrity and safety. It’s essential to consult local building codes and guidelines when planning HVAC installations.