In today’s world, electrical work is an essential part of many projects and DIY activities. Whether you’re working on your home’s electrical system, building a new structure, or tackling an automotive project, you may encounter the need to splice 6 AWG (American Wire Gauge) wire. Splicing wires correctly is crucial to ensure a safe and reliable electrical connection. In this article, we will guide you through the process of splicing 6 AWG wire step by step, covering everything you need to know.

Introduction

Splicing 6 AWG wire involves joining two or more wires together to create a secure and electrically sound connection. This article will walk you through the entire process, providing detailed instructions and tips to help you complete your splicing task successfully.

What is 6 AWG Wire?

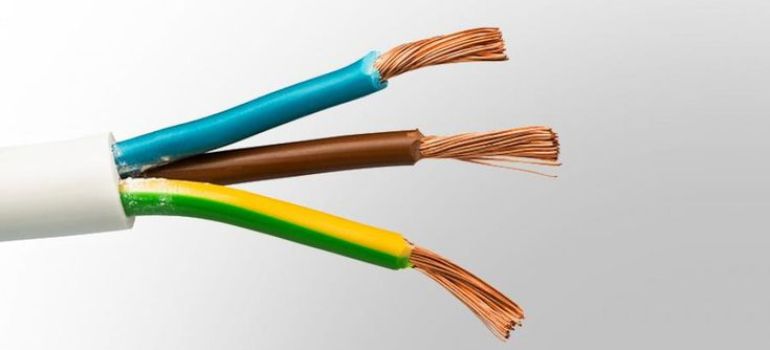

Before we dive into the splicing process, let’s understand what 6 AWG wire is. American Wire Gauge (AWG) is a standard used to measure the diameter of electrical wires. 6 AWG wire is relatively thick, suitable for applications that require a substantial current-carrying capacity, such as heavy-duty appliances, industrial equipment, or automotive wiring.

Safety Precautions

Safety should always be your top priority when working with electricity. Before you begin splicing 6 AWG wire, ensure you follow these safety precautions:

- Turn off the power source.

- Use appropriate personal protective equipment (PPE), including safety glasses and gloves.

- Work in a well-ventilated area.

- Keep flammable materials away from your workspace.

Tools and Materials

Gather the necessary tools and materials for the job, which may include:

- Wire strippers

- Wire cutters

- Wire nuts or soldering equipment

- Butt connectors

- Heat shrink tubing

- Heat gun or soldering iron

Preparing the Wire

To ensure a clean and effective splice, strip the insulation from the ends of the 6 AWG wires, exposing approximately 1 inch of bare wire.

Choosing the Right Splicing Method

The method you choose for splicing 6 AWG wire will depend on your specific project and preferences. The three most common methods are using wire nuts, soldering, and butt connectors.

How to Splice 6 AWG Wire Using Wire Nuts

Wire nuts are a convenient option for splicing wires. Simply twist the bare ends of the wires together and secure them with a wire nut. Ensure a tight connection and wrap it with electrical tape for added protection.

How to Splice 6 AWG Wire Using Soldering

Soldering provides a permanent and reliable connection. Heat the wires with a soldering iron and apply solder until it covers the splice evenly. Allow it to cool and solidify.

How to Splice 6 AWG Wire Using Butt Connectors

Butt connectors are ideal for joining wires in a straight line. Insert the stripped ends of the wires into the connector and crimp it securely using a crimping tool.

Heat Shrink Tubing Application

For added protection and insulation, slide heat shrink tubing over the splice and use a heat gun to shrink it in place. This seals the connection and prevents moisture or debris from interfering.

Testing the Splice

After completing the splice, test it to ensure it is secure and functioning correctly. Turn on the power and check for any issues or loose connections.

Common Mistakes to Avoid

Learn about common mistakes that people make when splicing wires to avoid potential hazards and ensure a reliable electrical connection.

Maintenance and Care

Discover how to maintain and care for your spliced wires to ensure their longevity and continued performance.

Additional Tips for Successful Wire Splicing

In addition to the steps and methods mentioned above, here are some additional tips to ensure a successful wire splicing process:

- Proper Insulation: Ensure that the insulation on the wire is stripped evenly and without damaging the conductors. This helps in maintaining the integrity of the connection.

- Tug Test: After completing the splice, gently tug on each wire to check if they are securely held together. If any wire comes loose, re-do the splice.

- Color Coding: If you’re splicing multiple wires together, consider using color-coded heat shrink tubing or electrical tape to keep track of each wire’s function, making troubleshooting easier in the future.

- Labeling: If your project involves a complex network of spliced wires, label each connection point to keep track of which wires go where, especially if they’re not all spliced at once.

- Professional Consultation: For complex electrical systems or critical applications, it’s wise to consult with a professional electrician. They can provide expert guidance and ensure that your splices meet safety and code requirements.

Advantages of Proper Wire Splicing

Understanding how to splice 6 AWG wire correctly offers several advantages:

- Safety: Properly spliced wires are less likely to cause electrical faults, reducing the risk of fire or injury.

- Reliability: A well-executed splice ensures a stable and uninterrupted flow of electricity, preventing disruptions in your electrical system.

- Compliance: Following correct splicing methods ensures that your electrical work complies with industry standards and local electrical codes.

The Importance of Regular Inspections

Even after successfully splicing wires, it’s crucial to conduct regular inspections to ensure the integrity of the connections. Over time, vibrations, temperature fluctuations, and other factors can affect the splices. Look for signs of wear, corrosion, or loose connections during your routine checks.

Where to Find Quality 6 AWG Wire and Splicing Materials

To ensure the success of your wire splicing projects, it’s essential to use high-quality 6 AWG wire and splicing materials. You can find these materials at local hardware stores, electrical supply shops, or reputable online retailers. Always choose trusted brands and verify that the products meet the necessary safety and performance standards.

Frequently Asked Questions (FAQs)

It is not recommended, as it can compromise the electrical integrity of the connection. Always use wires of the same gauge or higher.

Soldering provides a more secure and durable connection, but it requires skill and practice.

Reusing heat shrink tubing is not recommended, as it may not provide the same level of protection in subsequent applications.

A warm connection can indicate a problem. Check for loose wires or damaged insulation and re-splice if necessary.

Splicing underwater is a specialized task and should only be performed by professionals using waterproof connectors.

Conclusion

Splicing 6 AWG wire is a fundamental skill for anyone involved in electrical work or DIY projects. By following the steps and safety precautions outlined in this guide, you can create secure and reliable electrical connections. Remember to choose the splicing method that best suits your specific needs and always prioritize safety.

Now that you have the knowledge to splice 6 AWG wire safely and effectively, you can confidently tackle your electrical projects with confidence.